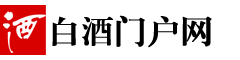

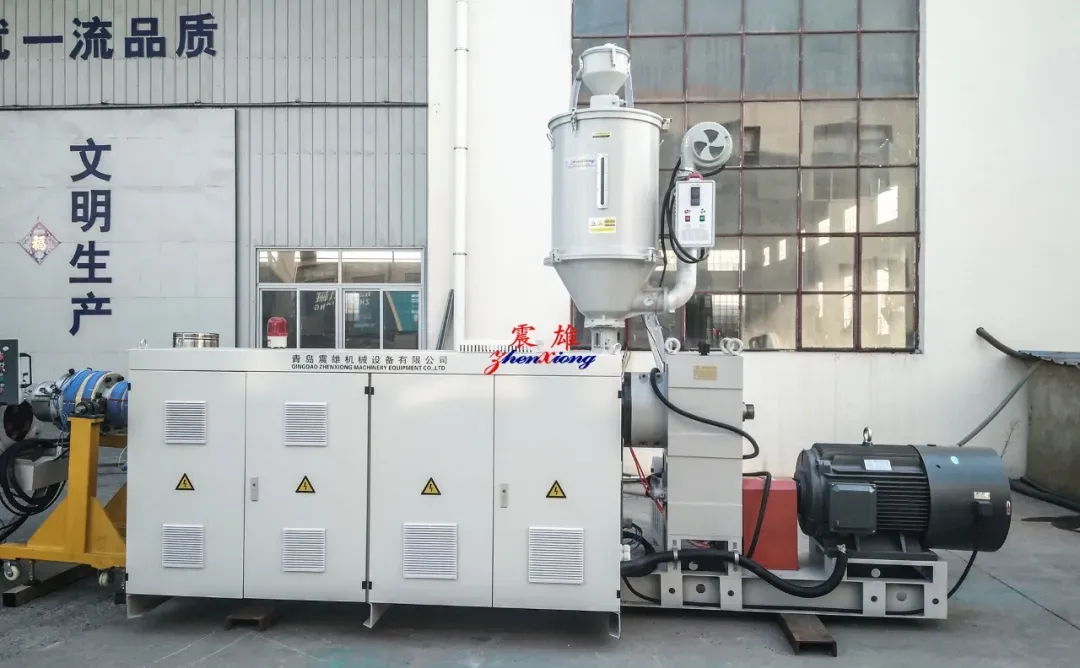

HDPE燃气管/供水管挤出生产线节能30%:优化螺杆结构+加料段逆向开槽设计,保证高产能的同时物料低温熔融,塑化均匀。挤出机加热系统升温快,主电机采用伺服电机,同等挤出量,节能效果好。

HDPE gas pipe/water pipe extrusion production line saves 30% energy: optimized screw structure + reverse slotting design of feeding section ensures high production capacity while the material melts at low temperature and plasticizes evenly. The extruder heating system heats up quickly, and the main motor uses a servo motor. With the same extrusion volume, the energy saving effect is good.

核心优势:

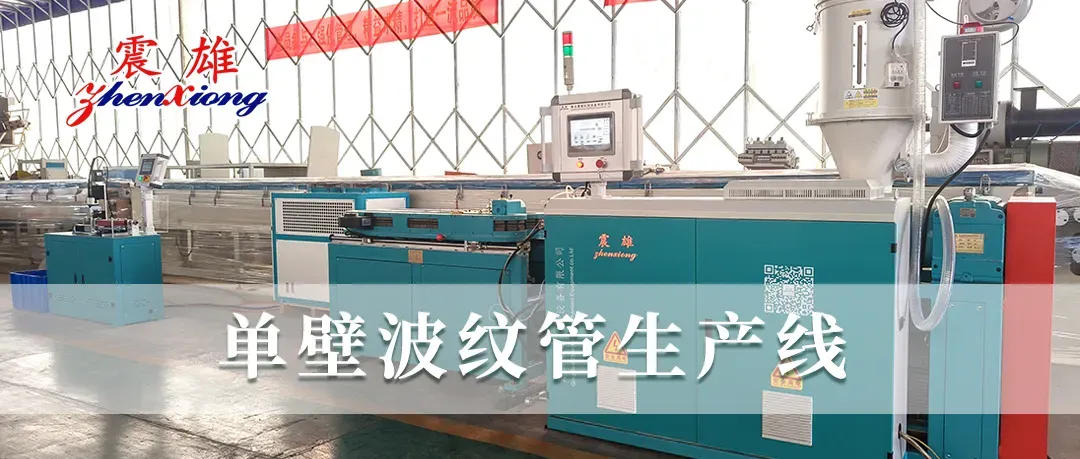

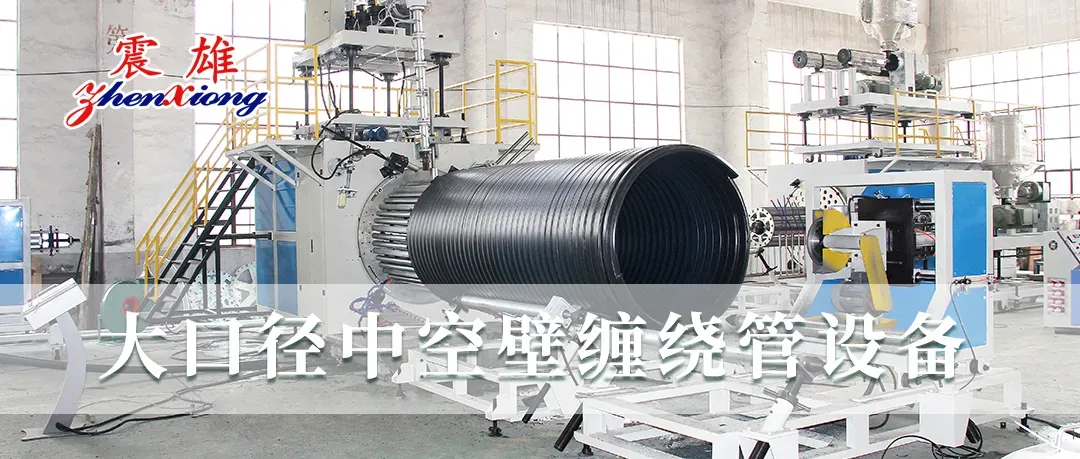

▶HDPE燃气管/供水管挤出生产线具备灵活的配置能力,通过更换管材模具及增加单螺杆挤出机数量,可生产双层、三层或多层复合管材,也可制造增强型复合管材。

▶生产线模具选用45#钢材质,经调质锻打与镀硬铬处理,具备优异的耐磨性与抗变形能力,确保长期运行的高精度与稳定性。

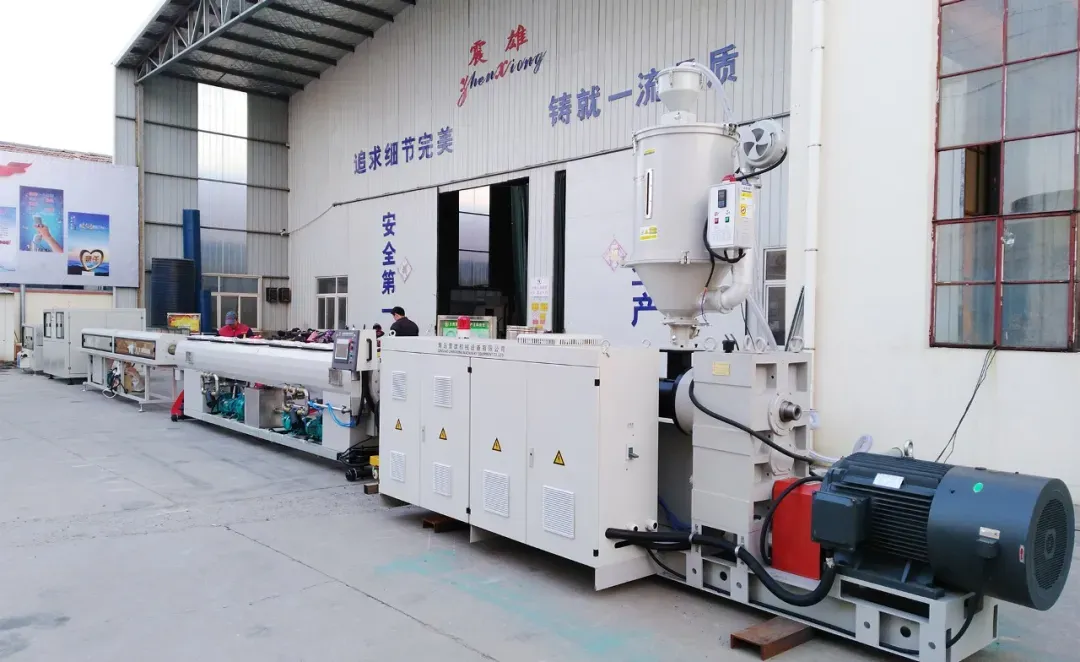

▶真空定型箱与喷淋箱拥有稳定的真空控制系统,可为管材提供均匀、充分的环绕冷却,并配备足够的冷却长度,保障管材成型质量。

▷The HDPE gas pipe/water pipe extrusion production line can produce two-layer, three-layer, multi-layer composite pipes or reinforced composite pipes by replacing the pipe mold and increasing the number of single-screw extruders.

▷The HDPE gas/water supply pipe extrusion production line mold is made of 45 # steel material, which has been quenched and tempered, forged, and plated with hard chromium treatment, making it more resistant to wear and tear, strong in deformation resistance, and high in precision.

▷The vacuum shaping box and spray box of the HDPE gas pipe/water pipe extrusion production line have a stable vacuum degree, which can provide uniform cooling capacity around the pipe and meet the sufficient cooling length of the pipe.

▶ 螺杆经特殊设计,加热迅速、塑化均匀;主电机配备伺服驱动系统,在同等挤出量下能耗显著降低,节能效果优异。

▶生产线采用德国INOEX品牌重力计量装置,有效保障米重控制精度,从而提升管材成型质量与一致性。

▶牵引结构设计合理,确保管材在运行中始终与牵引中心保持一致,便于用户快速调整与对中。

▶全自动无屑切割机实现管材端面光滑平整的切割效果,工作过程无噪音、无粉尘,能耗低且不产生废料,有助于用户节约成本。

▶系统集成西门子PLC控制单元,支持各项操作参数灵活设定,并实时显示于触摸屏界面,便于监控与调整。

▷The HDPE gas pipe/water supply pipe extrusion production line has a special screw design, fast heating and heating, and the main motor uses a servo motor. With the same extrusion volume, the energy-saving effect is good.

▷The HDPE gas pipe/water supply pipe extrusion production line adopts the German INOEX brand gravity metering device, which has high accuracy in meter weight control and improves the quality of the pipe.

▷The reasonable traction structure of the HDPE gas pipe/water supply pipe extrusion production line ensures that the pipe is always consistent with the traction center, which is convenient for users to adjust.

▷The end face of the pipe cut by the fully automatic chipless cutting machine of the HDPE gas pipe/water supply pipe extrusion production line is smooth, flat, noiseless, dust-free, and low in energy consumption, avoiding waste and saving materials for users.

▷The Siemens PLC control system of the HDPE gas pipe/water supply pipe extrusion production line allows the operating parameters to be freely defined and displayed on the display.

应用范围:

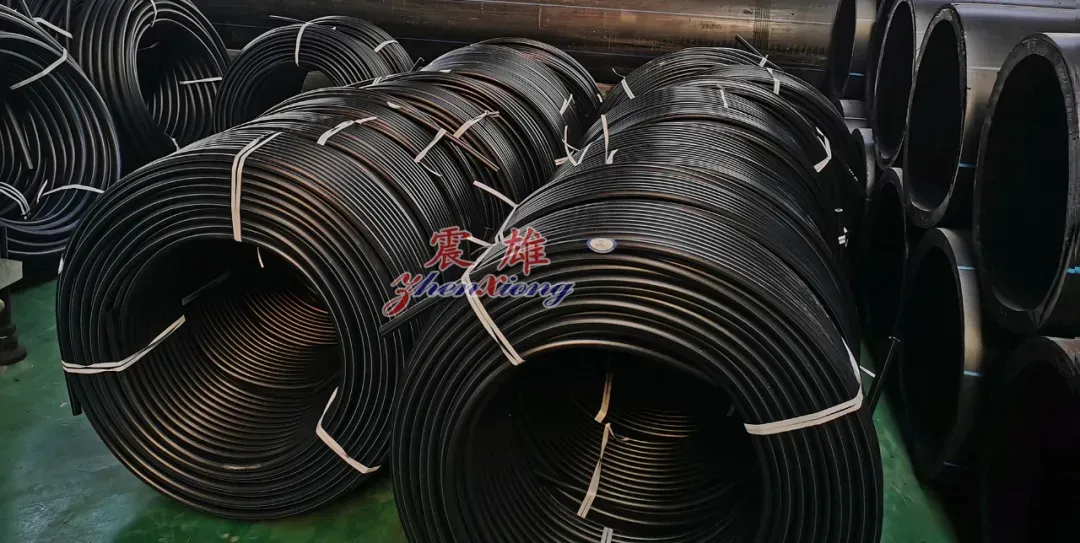

该生产线所产管材在刚度、柔韧性、耐热性、耐老化性、机械强度、抗蠕变性、耐腐蚀性及热熔连接性能等方面,均表现出显著优势。

其产品广泛应用于以下领域:

市政供水系统:城市自来水管网、城乡饮用水管道;

工业流体输送:化工、食品、林业、轻工、造纸等行业的料液输送;

农业灌溉:农用灌溉管道系统;

通信电力保护:邮电通讯线路、电力电缆保护套管;

矿山工程:矿山砂浆输送管道。

The pipes produced by this line have obvious performance advantages in terms of stiffness, flexibility, heat resistance, aging resistance, mechanical strength, creep resistance, corrosion resistance and thermal connectivity.

They are widely used in urban tap water pipe network systems, urban and rural drinking water pipes, chemical/food/forestry/light industry/papermaking/and other industrial liquid transportation pipes, agricultural irrigation pipes, postal and telecommunications lines, power wire protection sleeves, mining mortar transportation pipes and postal and telecommunications lines, etc.

我们公司已成立20余年